From launching the company in the family kitchen to distributing gourmet butters nationwide, Chef Shamy has grown through a powerful commitment to great product and smart choices.

What started as a holiday gift is now reaching more families with retail sales at Costco, Sam’s Club, Walmart, Kroger, and via private-label in grocery chains. When Chef Shamy needed a more efficient packaging process to keep up with booming demand, it was Ernest to the rescue. We like to think our stories align, except Ernest started in a garage and our products aren’t nearly as delicious. At the very least, we brought the machinery expertise Chef Shamy needed to move to this next level.

When packaging becomes a limiting factor

As the product’s national popularity grew, Chef Shamy found itself in need of a much larger production facility to keep up with increasing warehouse club, traditional grocery, and restaurant orders. In 2020, the company was going to move into a new 80,000 square foot location. With expanded kitchen space, production could dramatically increase, but the Chef Shamy team knew that hand packing shipping containers would be the limiting factor in their output.

The existing packaging system only allowed the company to run its production line at 40-50% capacity. Each packaging line required 4-6 people at the end to hand pack 24 tubs of butter into shipper boxes and then put them on rotating tables to be taped. With so many cooks in the packaging kitchen, the Chef Shamy team wouldn’t be able to meet production goals. The team knew there had to be a better way. They found it with Ernest.

“Ernest always goes above and beyond to make sure we have what we need to meet demand. From efficient supply of our standard boxes and materials to introducing us to the right automation equipment, the collaboration has delivered powerful business benefits.”

Sue Lyon

Procurement Manager Chef ShamyErnest & Chef Shamy: Butter Together

Chef Shamy had been an Ernest customer for a number of years, counting on the Salt Lake team for standard boxes, janitorial supplies, stretch wrap, and smaller equipment needs like a stretch machine and tape machine. In summer 2019, Ernest’s Client Automation Manager, Kurt Robb met with the Chef Shamy team to discuss plans for the new facility and their vision for what automation could add to the business. He visited the space and watched the production line to get a better sense of some of the pinch points that were limiting production volumes. The team evaluated Chef Shamy’s current machinery including the tubs being used, corrugated shipper boxes, the current speed of the line, and projected production volumes to identify the best fit equipment manufacturers.

With a clear understanding of the company’s equipment demands and limitations, Ernest invited the Chef Shamy team to join them at the Las Vegas Packing Exposition. The Ernest team, including Robb and Salt Lake City General Manager Gavin Jackson, had set up meetings with a variety of equipment manufacturers that the team had pre-screened to meet the unique demands of Chef Shamy. Based on what they saw at the event, quotes from various manufacturers, site visits to existing customers of the equipment, and detailed discussions about capabilities, Chef Shamy selected a Combi packaging system.

“Our relationship is super collaborative. They share options, discuss pros and cons, and we work together to solve any pinch points that appear in the production process. We appreciate their expertise.”

Daniel Shamy

Production Manager Chef ShamyCompounding efficiencies for their compound butters

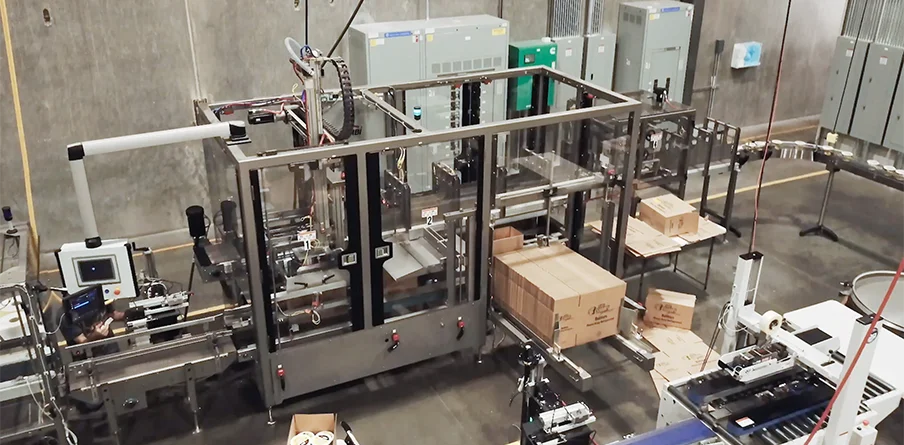

The Combi machine was delivered in late July 2020 in the midst of Covid-19 stay-at- home orders. While the situation wasn’t ideal for implementing new equipment, once everyone was back on the line and the Combi team could travel to help with installation, things went as smooth as, well, butter. The Ernest team was there for the installation and made sure that the Combi service tech personnel provided in-depth training for the Chef Shamy team. As with any new equipment, there are always things to check and adjust. By September, the line was fully up and working.

Spreading the productivity love

With its new automated packaging line in place, the Chef Shamy team has been able to double its production capacity with plenty of room for continued growth. Compared to previous run rates of 40-50% capacity, production now typically ranges from 75% to 80% of machine capacity.

The Combi packaging system does most of the packaging process: forming the boxes, filling them with butter tubs, adding stickers and adding lids. Just one person is needed per line to put the boxes on the pallet and monitor the machine. The Combi packaging system is a great fit for Chef Shamy and anytime they’ve had an issue, Ernest is just a phone call or text away.

“The Combi system never calls in sick. It’s never late or out on a long break. It doesn’t complain. And it’s always running at max capacity.”

Sue Lyon

Procurement Manager Chef ShamyFlavoring the future

During the pandemic, with more people cooking from home and discovering Chef Shamy’s irresistible butters, demand has boomed. The hope is that this growth will be sustained, so the next step on the horizon for Chef Shamy is to build a bigger kitchen that allows them to increase production capacity even more. They are also introducing a new sizing option with smaller butter servings packaged in clamshell containers. Chef Shamy is currently in the process of making some production adjustments to address this new unique opportunity and they know Ernest is always at the ready to help them deliver incredible flavor in great packaging to even more customers.