Ernest Opens Up Better Value: Product, Packaging, and Process

Martin Door makes beautiful custom-designed, premium garage doors that boast state of the art design, unique safety features, and fine craftsmanship. The company’s quality products help home- and business-owners throughout the world boost curb appeal while also enhancing security. When the company was looking to make its business more cost effective while maintaining the quality of its products, they didn’t have to look far for help.

Product: Ernest’s foot in the door

When Martin Door was acquired and a new management team came in, the company saw an opportunity to improve its packaging approach. Ernest Customer Relationship Manager Casey Williams connected with Mike Albert, Martin Door’s new VP of Operations to share how the depth of Ernest expertise extends well beyond boxes. Albert and Williams met and began discussing the various ways Ernest might be able to help—from sourcing more cost-effective suppliers to improving the packaging design.

“It was clear from the beginning that Ernest was willing to help in a lot of ways,” Albert says. “I started by taking them up on one thing at a time, and now they’ve helped us with all kinds of solutions.”

The relationship started with a simple product: adhesive. The adhesive Martin Door was using on a popular contemporary style door was not performing to the company’s standards, both in terms of the physical performance and the timeliness of delivery. It could also only be used for one specific application: to bond the interior plastic board to the exterior metal pans. When Williams asked why they were using that particular product, the answer didn’t surprise him: “We’ve always done it this way.” Ernest often runs into this in established businesses—and it’s often an opportunity for marked improvement.

Williams brought in an expert from a third-party vendor, adhesive manufacturer 3M, to review Martin Door’s needs: a glue that could bond a new, improved foam board and the metal face with no imperfections—keeping it rigid, flat, and solid—and cure quickly. After testing various samples, 3M identified a high quality automotive adhesive ideal for this application. This new adhesive strengthens the doors and makes them more effective in extreme temperatures. The new adhesive can also be used for multiple applications, which eliminated the need to purchase and inventory multiple adhesive drums. And best of all, it costs less than what they were using before.

“We can now offer a lower cost, higher quality door thanks to Ernest stepping up and bringing in the experts. Sales are through the roof.”

Mike Albert

Martin Door VP OperationsWith the improvement introduced by the new adhesive, Martin Door saw a triple digit percentage increase in units sold per month and anticipates sales will continue to rise. Ernest also helped Martin Door solve a leakage problem on its garage door windows by finding a superior tape sealant. According to Williams the new tape sealant has so far resulted in zero leaks and zero rejections in quality control. This increases manufacturing efficiency and reduces costs, while also improving the quality of their product. Once Ernest got its foot in the door with these improvements to Martin Door’s product, Albert and his team wanted to know, “What else can you help us with?”

Packaging: Ernest’s specialty

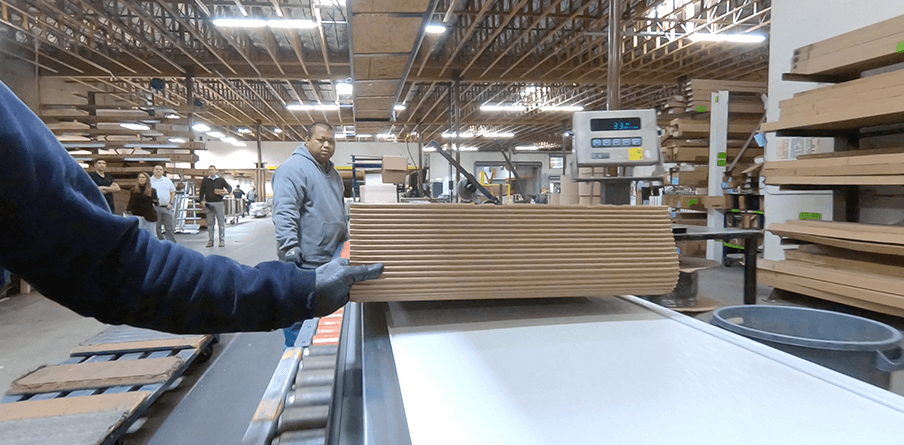

Each Martin garage door comes with an accessory kit containing the springs, track, rollers, fasteners, and other parts needed for installation. According to Albert, the company struggled with balancing the costs of this package with its value. They needed to protect the product from damage during shipment, but without spending too much, and they wanted to make the pack-out process more efficient. The goal was to create a package they could fill quickly, double-check for contents easily, and use as a do-all solution. As packaging design and engineering experts, Ernest knew how to solve this problem.

With input from Martin’s purchasing department the Ernest design team redesigned the unit box, making it easier to put together and more cost-effective. The new design is also multi-depth, so it’s able to hold the accessories for two different types of door. This enables Martin Door to save money by purchasing a single SKU for use on multiple products. The company saw 18-25% savings as a result of volume pricing.

Ernest also applied its packaging know-how to Martin Door’s pre-installation packaging. Martin Door is located in Salt Lake City but sells to dealers and direct buyers throughout the world, with focus on the West Coast from Canada to the southern U.S. border. To prevent damage during shipment they use a multi-layer, L-shaped cardboard corner board to protect the doors, plus rolled corrugate, stretch-wrap, and bands to hold the protective packaging in place.

Martin Door had been using the same corner board for years—again, because that’s how they’d always done it. While the corner board was protecting the product, the cost was a problem. Ernest suggested switching to a plain craft corner board, which offered the same strength protection at a lower cost.

“Ernest helped us drive the price down to balance the cost of damages and returns with the cost to package each door, whereas before we were overspending on packaging.”

Mike Albert

VP OperationsProcess: Streamlining and strengthening

Now that Ernest has proven its product value to Martin Door, the plan is to help the company cut costs and improve processes across the board. According to Albert, Williams has already helped identify and solve a couple pain points—for example they stopped using tape and started using banding machines instead because it was more efficient from both a product and process standpoint. The next step is to bring in Ernest’s process and logistics experts to apply the company’s proven methodology

to help optimize Martin Door’s entire finish assembly and packaging operation.

Ryan Reid, General Manager for Salt Lake City, explains, “We basically said you have to be transparent with us and we’ll help you find better ways of doing things.” Albert and his team at Martin Door are excited at the prospect and anticipate a lot of takeaways.

Ernest’s design specialists apply a simple but effective process to identify opportunities to help companies reach their productivity goals: definition, observation, analysis, and recommendations. Paired with Ernest’s CURE philosophy, the process is sure to yield even more value for Martin Door by increasing efficiency and reducing costs.

The Ernest team plans to start working with the Martin Door operations team on process optimization as soon as the weather cools off and their sales slow down for the season. That way they’ll be ready to open their doors to a new selling season with a whole new outlook—and maybe a new way of doing things.

Value you can—and can’t—measure

In addition to looking at process optimization, Ernest and Martin Door are working on finding a single-box solution for shipping the company’s doors, which they hope will reduce freight costs. Martin Door is also looking at Ernest’s janitorial supplies as one more avenue for cleaning things up and reducing costs.

Since they began working with Martin Door, Ernest has delivered measurable business value by taking costs out of both product and packaging, while improving the quality of both. This has enabled Martin Door to pass that savings on to dealers and end customers, while at the same time improving margins. Albert says, “We call that a win-win-win.”

Ernest has also delivered value that you can’t put a number on. Based on changes Ernest helped them make, Martin Door’s dealer response rate has risen, dealer approval levels have improved, and customer satisfaction has gone up as they’ve addressed quality and cost issues more proactively. That’s the real measure of working with a company that’s more than a solutions provider: With Ernest you get a partner you can count on for the long-term.