The State of the DIM Weight Union Infographic

July 07, 2016

The costs of oversized packaging are felt in stages of the supply chain. Boxes that are too big means fewer packages fit on a truck, which means more trucks need to be on the road. Too much material also means consumers have to deal with the hassle of breaking down and disposing of it. In turn, more material makes its way into landfills.

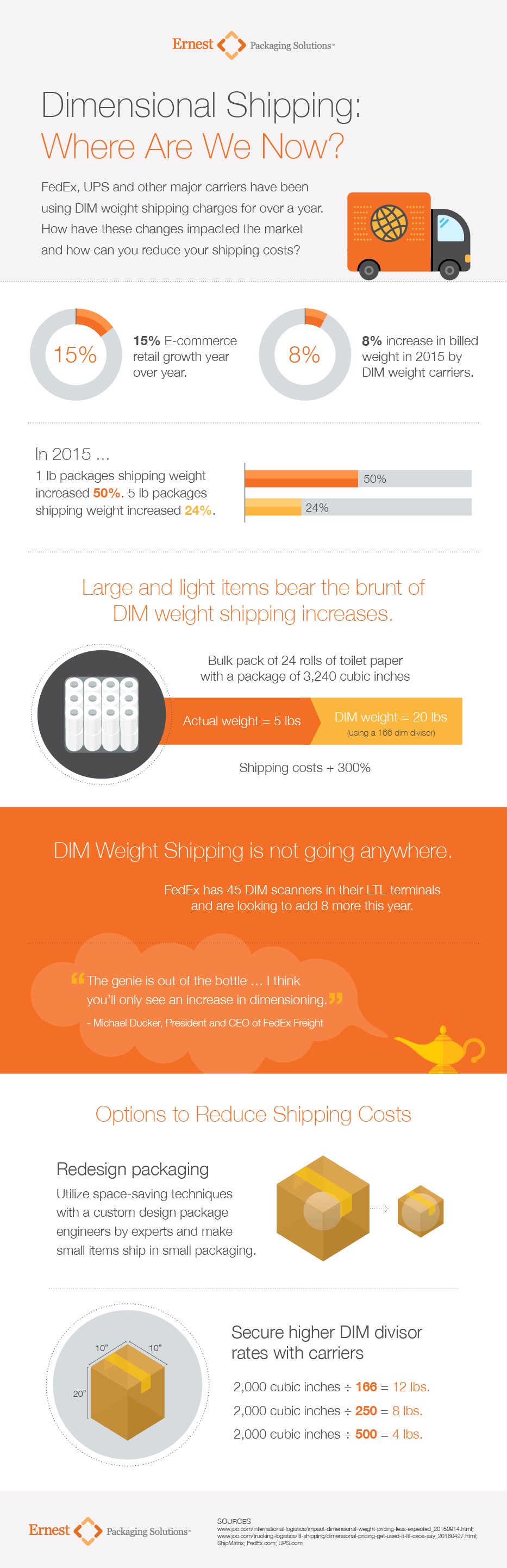

Oversized packages also make cargo costly for FedEx, UPS and other shippers which is why DIM weight freight became the norm over the last 12 months. In short, shipping charges were not in line with the actual costs of delivery. Precious real estate taken up by bulky, but light, boxes was hurting carriers’ bottom line.

The response was to charge freight by a calculation of size and weight as opposed to just weight and additional surcharges. UPS implemented a new handling fee on boxes 48 inches or longer—one foot shorter than their previous surcharge size of 60 inches just last month.

What has changed in the packaging industry one year into DIM weight shipping? Let’s take a look.

Innovative companies are working to find ways of shaving off inches of their boxes while still maintaining light and engaging packaging.

“There are many ways we can adjust the size of packages for DIM weight efficiency,” says Ernest’s Director of Design Solution Mike Martinez. “We have the latest in packaging technology to create smaller, yet more efficient air cells for cushioning. But sometimes you just need to rethink the structure from the ground up.”

Find Your DIM Weight

Need to know if you’re hitting your weight goals? Download our DIM Weight app available in the Apple App Store now. Our DIMcalc does that math for you just enter the dimensions and your measuring method and get an accurate DIM weight on the spot!

Need to talk DIM weight and all things shipping design and logistics? Give us a call today to learn to manage DIM weight changes and make beautiful packaging that doesn’t hurt your bottom line.