Saving time, space, and money for Limitless USA

Limitless USA does a booming business selling refurbished iPads, iPhones, and Macbook Pros, as well as Google and Samsung smartphones. In fact, last year the company was doing so well they started having trouble keeping up with demand. During their peak season from September to December, some days were so busy they had to stop taking orders until their shipping department could catch up. Limitless was also experiencing losses due to damaged devices during shipment. To keep putting technology into people’s hands and driving sales, they needed to find a better way. So naturally, Ernest came to the rescue.

Driving efficiency down the line

Ernest Client Relations Manager Kyle

Hand visited the Limitless facility to see how they do things and find opportunities for improvement—starting with the box. Limitless was using premium jewelry-type boxes to ship both iPads and iPhones. While the boxes had a nice look and feel, they had to be put together by hand, which was time-consuming and required multiple workers. Hand suggested they use a plain white roll-end-tuck-top (RETT) box, which still mimicked the look and feel of Apple packaging but without the luxury price tag. Plus, RETT boxes only require a few folds and tucks to make them ready to use, so making this change allowed Limitless to speed up their production line considerably.

Next, Hand had Ernest’s automation specialist, Rudy Chavez, visit the facility. Chavez showed the Limitless team how to improve efficiency by packing in a line. Just like an assembly line at a manufacturing plant, a shipping line gives each person one job to do: one person prints labels, one bags the product, one checks the invoice, one applies the label, and so on. This method speeds up the packing and shipping process so they can get more orders out the door, and keep filling new orders as they come in. Ernest also replaced the tape they were using with automatic tape dispensers that deliver just the right amount of tape for each box size, creating consistency while cutting down on waste.

To accelerate the process even more, Chavez also showed Limitless an auto- bagging system, which will eliminate one step in the line completely and save the team even more time. The company plans to implement this system after their peak season ends, when they can afford a few hours to make the transition.

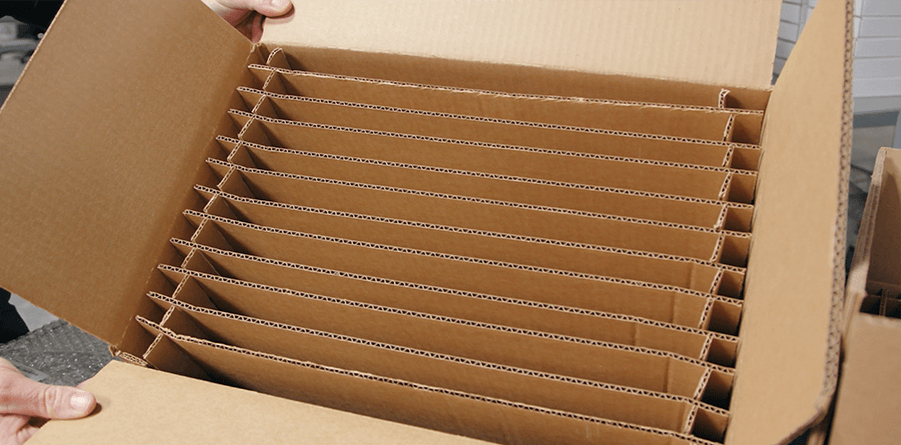

Ernest also helped Limitless find a solution to their bulk shipping problem. Rather than replacing the larger box, Ernest’s engineering gurus found a way to use it smarter, so product handling during shipment caused less damage. According to Magcalas, “The solution Ernest came up with was to put slots inside the box to reinforce its stability.” This simple but effective change protects devices during shipment by holding them in place, preventing them from moving around and damaging each other.

Technology for the masses. Sustainability for the planet.

Limitless first opened 26 years ago with the mission to help people “become limitless” by giving them access to the technology they need to succeed. By refurbishing used devices, they can make technology more affordable and make people more powerful. As electronics use began to proliferate, electronic waste did, too. Limitless is also proud to help lessen environmental impact by refurbishing and re-selling used devices, which prevents them from ending up in landfills.

Limitless ships their products out of an eight-building complex in Las Vegas,

NV. The company helps organizations find the best quality devices at the most affordable prices, and get the most out of their investment by customizing and configuring devices and providing the best possible support. In addition to selling to individual end users through e-commerce websites, they provide hardware for a number of industry verticals, from agriculture to insurance, and also sell to distributors.

Challenge: Productivity and protection

Delicate devices call for special care when it comes to packing and shipping. Limitless had a team of people working to package and fulfill orders. For each one, they had to build the shipping box, put the product or products into bubble wrap bags, place the bagged product into the box, tape it shut, and apply a shipping label. Keeping enough packing supplies on hand to keep up with such a large volume of orders was taking up a lot of space in the company’s warehouse. And the whole process was inefficient, slowing the business down and leading to limitations when their sales were surging.

In addition to backed-up orders, Limitless was also experiencing losses due to damage when shipping their products in volume to wholesalers. With clients that buy between 100 and 1000 devices at a time, Limitless was shipping 20-30 individually bubble-bagged devices together using larger boxes. During shipment, the contents were moving around resulting in damage—a cost that can add up quickly. Jim Magcalas, General Manager of Limitless, explains, “Our products range from $200 to $1000. If we ship 20 and two of them break, that can cost us $500 to $700 on average.”

Limitless needed a way to improve the efficiency of their shipping department so they could keep up with growing demand, and a more protective solution for shipping devices in bulk to reduce costly losses. Plus, they needed a better way to manage their packaging inventory needs. Luckily, the team at Ernest Packaging Solutions knew how to solve all their problems.

“ The new box is three times faster to assemble, which means we can delegate different tasks to the staff who were doing that before. In our busy season, we have more room for growth because we only need one person to build boxes.”

Jim Magcalas

General Manager Limitless USA“Ernest has helped us solve a lot of business challenges. Just-in-time inventory saves us valuable space, which has allowed us to expand and better organize the warehouse.”

Jim Magcalas

General Manager Limitless USAAdding value at every step

Since working with Ernest to improve their packaging and their processes, Limitless has been able to free up staff members to put their skills to work toward more valuable efforts than just building boxes. They’ve increased the efficiency of their shipping department, which allows them to focus on growth—especially during the peak buying season in the last quarter of the year. And they’ve reduced their losses from damage during shipment. Since they began using the new slotted box designed by Ernest, Limitless has had zero complaints from customers.

Time and money aren’t all Limitless is saving. The company is also saving space with Ernest’s just-in-time inventory management. With orders ranging from 15,000 to 20,000 units a month, they were dedicating a lot of warehouse space to house their packaging solutions—with up to 20 pallets on the floor at a time. Now Ernest does it for them, holding everything Limitless needs in their nearby Las Vegas facility, and delivering it on demand. If they receive 2,000 orders in a day but only have 1,000 boxes on hand, all they have to do is pick up the phone and call Ernest and they’ll have what they need the same day.

For Limitless, Ernest does more than provide solutions—they are a partner the company can rely on to help them meet all their packaging and shipping needs, today and tomorrow. Limitless is in the process of launching new products, including desktop iMacs that require a new packaging solution to protect this bigger, heavier device during shipment. Ernest is working with Limitless to come up with the best possible solution to meet this new need. The future holds “limitless” possibility. Whatever the company needs, Ernest will be right there with them ready to tackle any challenge and get the job done right.

“ Whenever I call Kyle, he’s always there—and he never says no. Rather than just selling me off-the-shelf solutions, Ernest can customize solutions for whatever we need. That’s a huge benefit to our business.”